12 Things I Wish I'd Known About Predictive Maintenance Software Before Implementing It

- December 02, 2023

- 3 minutes

The exploration into the world of predictive maintenance software is akin to venturing into a labyrinth of complex algorithms, machine learning models, and real-time data streams. As we delve into this intricate maze, let's illuminate the path with hindsight's torchlight, unearthing twelve revelations I wish I'd been privy to before embarking on this journey.

-

Understanding the Basics: Predictive Maintenance Software:

Predictive maintenance (PdM) software is not simply a fancy term. It is a sophisticated tool that utilizes machine learning algorithms and data from various sources to predict equipment failure before it occurs. This proactive approach ensures a higher level of efficiency and productivity, reducing downtime and maintenance costs. It is an application of the chaos theory's butterfly effect- a miniscule event such as a slight change in machine vibration may lead to catastrophic equipment failure if not addressed.

-

It Isn’t a Magic Wand:

It's important to dispel the myth that PdM software is a panacea. It isn't a magic formula that will instantaneously resolve all maintenance challenges. The software is a tool, the effectiveness of which is contingent upon the quality of data fed into it and the expertise of the team interpreting its outputs.

-

The Complexity of Implementation:

Implementing PdM software is a complex process that involves several steps including data collection, model training, and validation, among others. It is the equivalent of activating a neural network – it needs to be meticulously programmed to analyze, learn, and predict.

-

The Importance of Data Quality:

Garbage in equals garbage out. The efficacy of PdM software is heavily reliant on the quality of data it processes. Inadequate or incorrect data can lead to false predictions, potentially resulting in unnecessary maintenance or overlooked failures. This is an application of the law of large numbers, where the accuracy of results increases with more data.

-

The Costs Can Be Prohibitive:

PdM software can be a costly investment. High initial capital outlay, recurring costs related to data storage, software updates and potential additional costs for data cleaning or acquisition can add up. It's important to do a cost-benefit analysis, evaluating these costs against potential savings from predictive maintenance.

-

The Integration Challenge:

Integration with existing systems can be a major hurdle. If your current infrastructure is not geared to handle the computing power or data capacity required by PdM software, significant additional investment may be required.

-

Training is Crucial:

Implementation of PdM software requires a skilled workforce well-versed in data interpretation and machine learning models. The knowledge gap can be substantial and investing in training is essential for successful implementation.

-

Flexibility is Key:

Predictive maintenance software should not be a rigid system, but rather a flexible tool that can adapt to changing circumstances. This is particularly true in the rapidly evolving landscape of Industry 4.0, where the ability to pivot and adapt is critical.

-

Monetizing the Investment:

It is important to remember that while PdM software can be a game-changer, it is ultimately a tool to enhance productivity and efficiency. The ROI should be evaluated not just in terms of cost savings from prevented downtime, but also from an overall productivity and efficiency perspective.

-

The Role of Data Security:

With the proliferation of cyber threats, data security is paramount. This is especially relevant in the context of predictive maintenance, where sensitive operational data is being processed and analyzed. Ensuring robust security measures are in place is a non-negotiable.

-

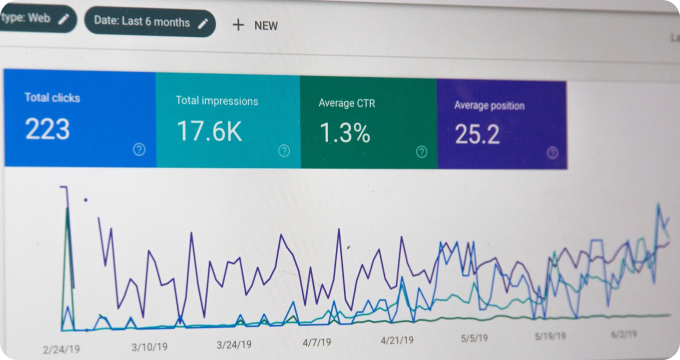

The Power of Real-time Analytics:

While predictive maintenance inherently implies future predictions, the real power lies in its ability to provide real-time analytics. This allows for immediate corrective action based on real-time data - a powerful tool in any maintenance strategy.

-

It's a Continuous Learning Process:

The implementation of predictive maintenance software is not a one-time event. It is a continuous journey of learning and adapting to optimize the system's effectiveness. It's a dynamic process, much like the Heisenberg's Uncertainty Principle, where the more precisely one property is measured, the less precisely the other can be controlled.

In summary, predictive maintenance software is a powerful tool that can revolutionize maintenance strategies. However, to unlock its full potential, it's crucial to understand its intricacies and challenges. Armed with these insights, one can navigate the labyrinth of predictive maintenance with confidence and precision.

Learn More

Unleash the power of foresight and optimize your operations by diving deeper into our enlightening blog posts on predictive maintenance software. For an unbiased, comprehensive view, the reader is encouraged to explore our meticulously curated rankings of the Best Predictive Maintenance Software.

Popular Posts

-

Predictive Maintenance Software Industry Report: Unveiling Key Findings and Crucial Insights

Predictive Maintenance Software Industry Report: Unveiling Key Findings and Crucial Insights

-

The Future of Predictive Maintenance Software: Predictions and Trends

The Future of Predictive Maintenance Software: Predictions and Trends

-

Ask These Questions to a Predictive Maintenance Software Provider to Choose the Right One for Your Business

Ask These Questions to a Predictive Maintenance Software Provider to Choose the Right One for Your Business

-

How to Hire the Right Predictive Maintenance Software Provider

How to Hire the Right Predictive Maintenance Software Provider

-

12 Things I Wish I'd Known About Predictive Maintenance Software Before Implementing It

12 Things I Wish I'd Known About Predictive Maintenance Software Before Implementing It